Outstanding Projects

Stücki Village

Swiss Prime Site AG

Pavilion | Special Construction

Kinematic Hand for Verdi’s Rigoletto

Pavilion | Special Construction

Home of Chocolate

Brand | Experience World

Swiss pavilion – Expo 2020

Präsenz Schweiz

Pavilion | Special Construction

Kennedy Pavillon

Kennedy Luxury Group

Pavilion | Special Construction

House of Geberit

Geberit International AG

Tradeshow | Event

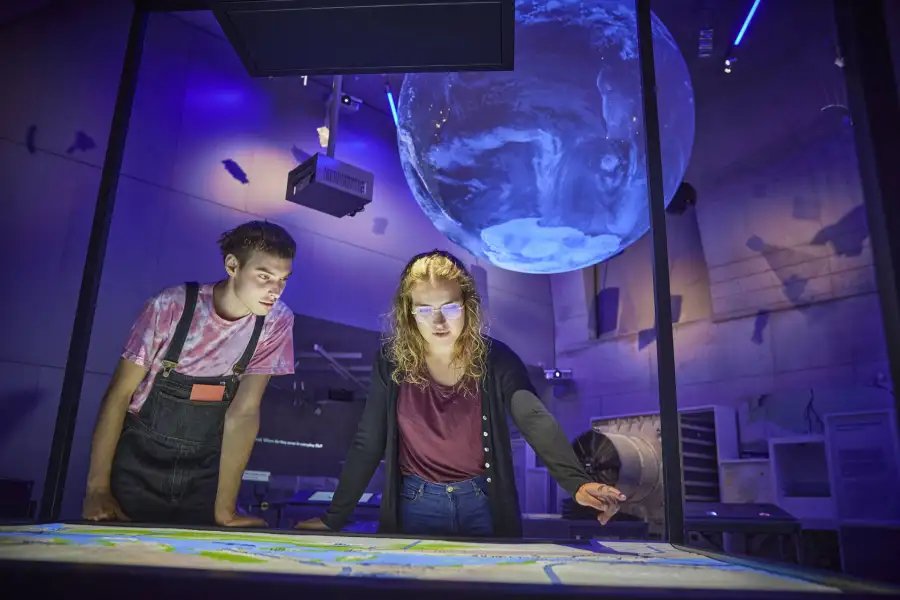

Museum of the Future

Deutsches Museum Nürnberg

Brand | Experience World

Sustainable exhibition stand system at Giardina

Giardina

Retail | Interior Design

Is Your Project Next?

Let's explore new horizons together – contact us and become part of our network.

Let Your Vision Become Reality