Could entire cities act as raw material deposits, and old pipes from nearby be reused for new buildings? Circular building is gaining importance today. Using existing materials rather than extracting new ones has become the goal of innovative organizations such as “Circular Economy Switzerland” and the “Madaster” platform.

But what concrete possibilities do buildings offer for resource-efficient construction? What does it mean to build circularly, and what can be achieved by rethinking an entire industry? Here’s our perspective.

Circular building – making “new” from “old”

The construction industry is at the cusp of a deep-reaching transformation. What does this mean for the material flows of a sector that is behind 80 percent of all the waste generated in Switzerland?

Circular building seeks to use materials in closed cycles – for as long as possible and ideally without degrading their quality.

Circular building seeks to use materials in closed cycles – for as long as possible and ideally without degrading their quality. The goal is to avoid further depleting raw material resources and to work, instead, with secondary resources – recycled primary materials. The waste from an old product is, thereby, fully transformed into a new one. Proper planning and material selection make it possible to feed resources into infinite cycles and reuse them again and again.

Cradle to cradle – usable nutrients, not waste

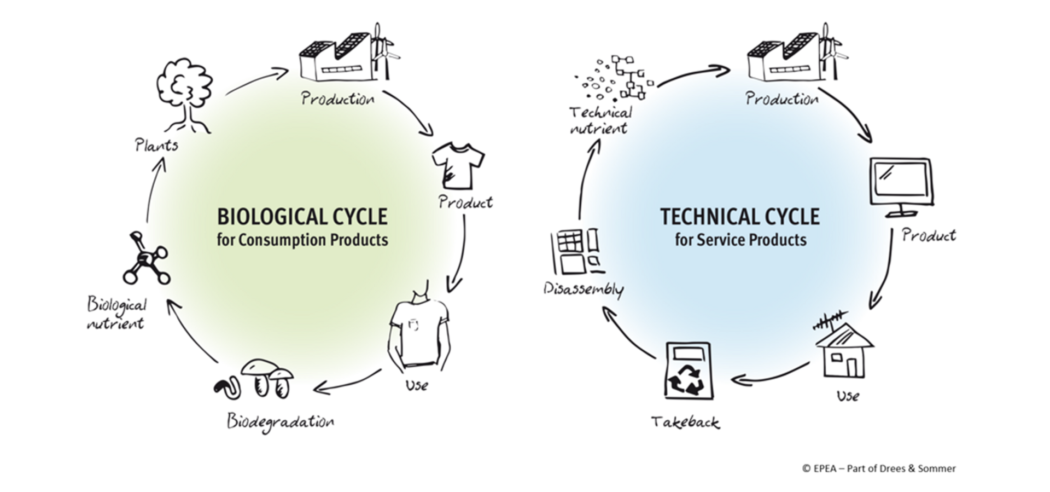

In the 1990s, Prof. Dr. Michael Braungart, William McDonough, and EPEA Hamburg developed a design principle to foster the development of economic systems that are compatible with the environment. “Cradle to cradle” seeks to slow down and close material cycles. All ingredients used should be chemically safe and recyclable.

Cycles can be broken down into two categories. In technical cycles, raw materials for products and buildings are used in a way that maintains their quality, allowing them to be decomposed into single-variety source materials and reused. Biological cycles, on the other hand, deal with fully degradable materials.

Design for lifetime extension

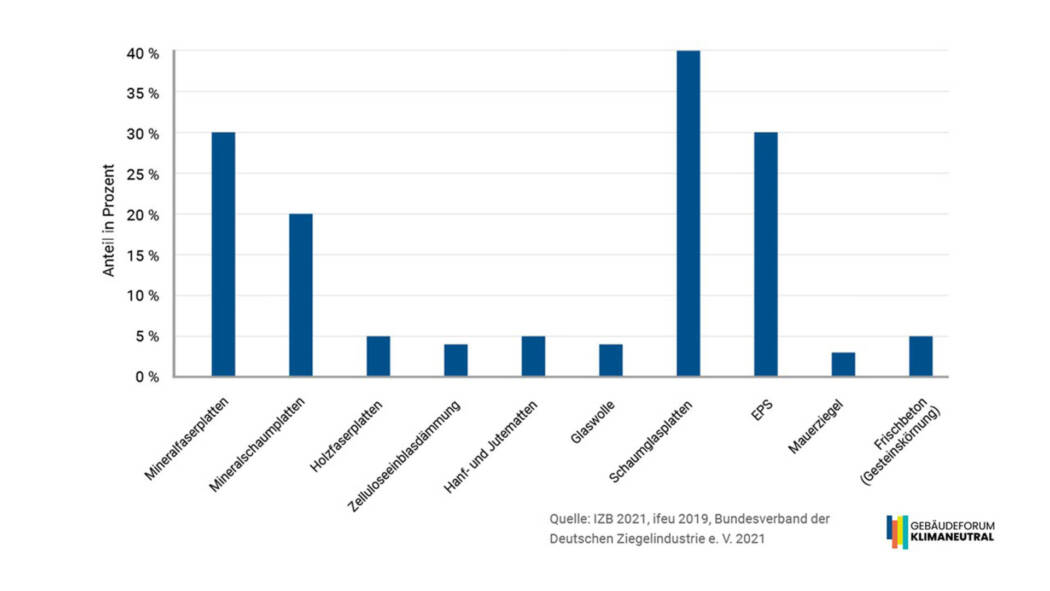

Already today, some materials achieve higher recycling rates than others. Glass and steel, for example, are already fed back into production in vast quantities. Fresh concrete and wood fiberboard tend to score lower. The main reason behind this is differing quality requirements.

Expomobila already acts as a sustainable general contractor. At the EXPO 2020 in Dubai, our team built the Netherlands Pavilion using circular construction methods. Ninety percent of the materials used were recycled, giving, for example, 2000 tons of steel and an elevator a second life. After the World Expo, they returned to where they had come from for further reuse. And that isn’t all. The floor tiles and the acoustic walls installed by our team were made up of bio-based mycelium material – the vegetative part of mushrooms.

In Switzerland, the revised federal law on public procurement (PPA), which came into force on January 1, 2021, charted a new course toward greater circularity in the Swiss construction industry.

Urban mining – new buildings as future material depots

Urban mining considers entire cities, housing developments, and infrastructure as mines for raw materials. Pipes or materials for old buildings can, for example, be reused. Several platforms and organizations are already specializing in these as second-hand providers. They offer used components and recycled materials to facilitate the practical implementation of circular planning and, in a later stage, deconstruction.

Practical innovations – a digital material passport

Sustainably closing material cycles depends on a constant exchange of information at any time, with location-independent access. A so-called material passport can centrally store information on the source, quality, carbon footprint, and the reusability of construction materials. Digitally capturing the entire building stock using a database and a material inventory makes it possible for companies with a sustainable mindset to cooperate in the use of secondary raw materials.

Circular Economy Switzerland

Acting as a platform for coordination and exchange, “Circular Economy Switzerland” is all about circular building in Switzerland. Publishing news stories about the circular economy every two weeks, the website keeps members and readers updated.

Partner websites such as the “Circular Hub” offer the possibility to network with other companies and participate in workshops. The Swiss knowledge and networking platform supports and advises companies in their transition towards a circular economy, promoting a new, circular understanding of growth in place of linear “take-make-waste” thinking.

The Swiss material cadaster, “Madaster,” is dedicated to creating a digital material passport for new buildings and existing structures. Cataloging building components offers insights into their separability, their bound CO2, and the toxicity of the materials and products used. It also makes it possible to determine whether materials and products can be reused and where required secondary raw materials can be mined.

Pioneers and role models: Let yourself be inspired

Whether it’s the Basler Pavilion 2022 or redevelopment plans for SBB wagon warehouses, Switzerland has a growing number of trailblazing circular building projects. Consider the redesigned head building of Hall 118 at the Sulzer site, which gave Switzerland’s first large industrial area a second life: The resulting CO2 footprint was 60% lower than it would have been had it been rebuilt from scratch. Luminaries such as Barbara Buser from the construction office “in situ” made this possible. Driven, innovative founders like Marloes Fischer from the “Circular Hub” platform, mentioned earlier, are pointing out new ways forward for the construction industry.

Become part of the circular big picture and join Expomobilia on our journey towards a sustainable and resource-efficient future.

Temporary and sustainable

We proudly bring high-quality projects to life using sustainable, resource-conscious materials and processes. Like the four national pavilions built for the World Expo in Dubai!

Contact us